全部

▼

搜索

熱搜:

位置:中冶有色 >

> γ′ 相對高鎢鎳基高溫合金拉伸和持久變形行為的影響

551

編輯:中冶有色技術(shù)網(wǎng)

來源:韋林,周思耕,盛乃成,于金江,侯桂臣,王標,權(quán)佳,周亦胄,孫曉峰,康涌

551

編輯:中冶有色技術(shù)網(wǎng)

來源:韋林,周思耕,盛乃成,于金江,侯桂臣,王標,權(quán)佳,周亦胄,孫曉峰,康涌

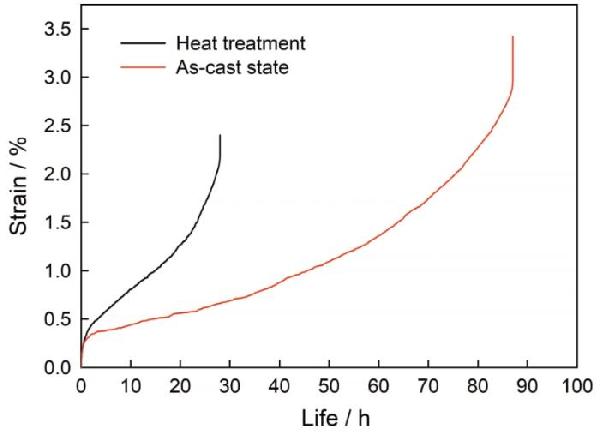

| Rp0.2 /MPa | Rm/MPa | A/% | Z/% | |

|---|---|---|---|---|

| As-cast | 936 | 1054 | 4.0 | 10.0 |

| Heat-treatment | 775 | 1040 | 6.5 | 11.0 |

分享 0

分享 0

舉報 0

舉報 0

收藏 0

收藏 0

反對 0

反對 0

點贊 0

點贊 0

中冶有色技術(shù)平臺

中冶有色技術(shù)平臺 2025年03月25日 ~ 27日

2025年03月25日 ~ 27日  2025年03月28日 ~ 30日

2025年03月28日 ~ 30日  2025年04月11日 ~ 13日

2025年04月11日 ~ 13日  2025年04月24日 ~ 27日

2025年04月24日 ~ 27日  2025年04月27日 ~ 29日

2025年04月27日 ~ 29日