全部

▼

搜索

熱搜:

1020

編輯:中冶有色技術網(wǎng)

來源:毛建軍,富童,潘虎成,滕常青,張偉,謝東升,吳璐

1020

編輯:中冶有色技術網(wǎng)

來源:毛建軍,富童,潘虎成,滕常青,張偉,謝東升,吳璐

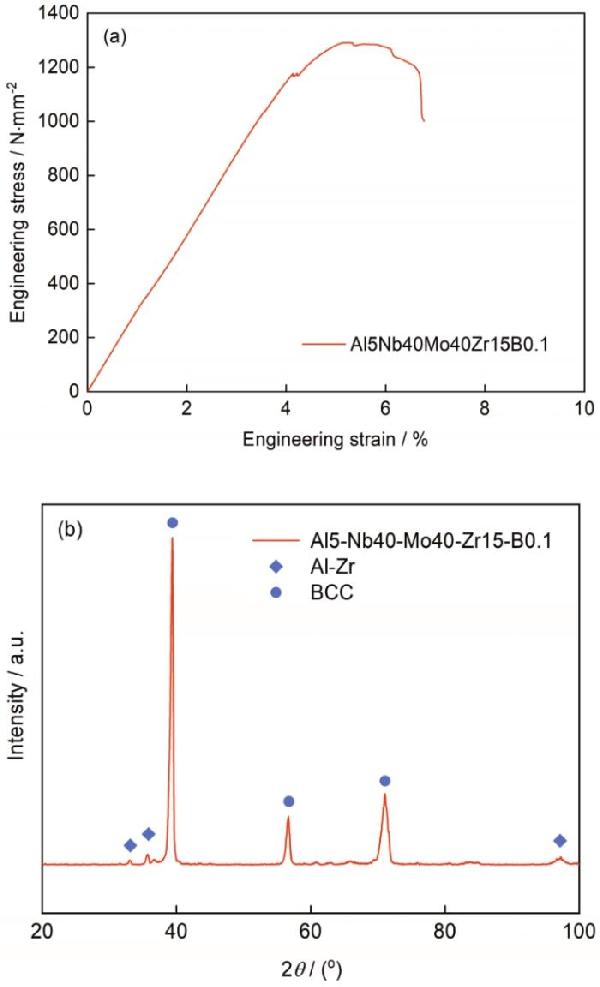

| Alloy |

σc0.2 /MPa |

σp /MPa |

εp /% |

|---|---|---|---|

| Al5Nb40Mo40Zr15B0.1-cast | 1180 | 1274 | 4.8 |

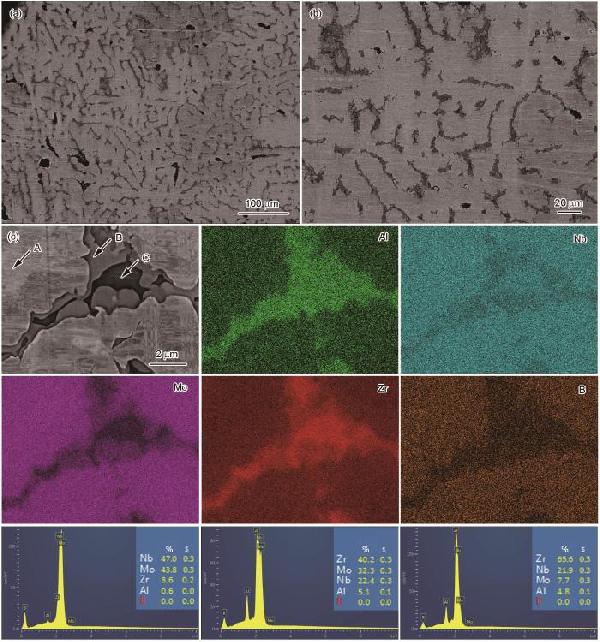

| Points | Al | Nb | Mo | Zr |

|---|---|---|---|---|

|

Nominal composition A (white dendrite rigon) B (gray interdendritic rigon) C (black interdendritic rigon) |

5 2.06 15.65 14.67 |

40 46.89 19.97 19.43 |

40 42.31 27.88 6.62 |

15 8.74 36.50 59.28 |

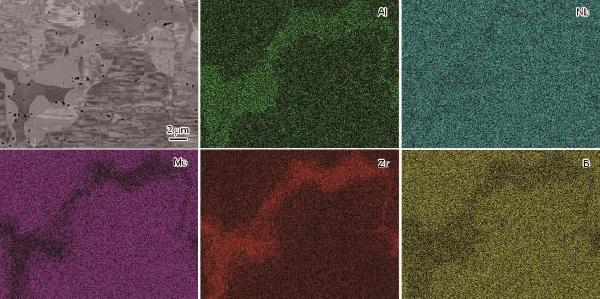

| Points | Al | Nb | Mo | Zr |

|---|---|---|---|---|

|

a1 a2 a3 a4 a5 a6 |

6.84 9.83 1.97 0.85 1.93 9.17 |

9 21.7 37.67 40.16 39.35 19.21 |

12.76 27.37 45.46 44.07 36.84 27.36 |

71.4 41.09 14.91 14.92 13.15 44.26 |

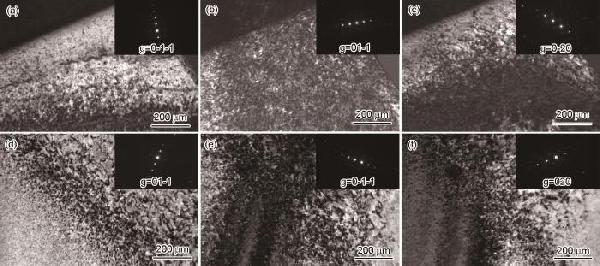

| Points | Al | Nb | Mo | Zr |

|---|---|---|---|---|

|

d1 d2 d3 d4 d5 d6 d7 |

2.37 1.88 1.91 2.65 6.61 4.48 4.31 |

42.27 42.64 42.84 45.38 23 11.01 20.61 |

41.46 39.18 38.62 34.76 21.36 9.55 5.25 |

13.89 16.3 16.64 17.21 49.04 74.96 69.83 |

分享 0

分享 0

舉報 0

舉報 0

收藏 0

收藏 0

反對 0

反對 0

點贊 0

點贊 0