全部

▼

搜索

熱搜:

位置:中冶有色 >

> 等溫處理時(shí)間對(duì)觸變擠壓錫青銅軸套的組織和性能的影響

1085

編輯:中冶有色技術(shù)網(wǎng)

來源:肖寒,周瑀杭,陳磊,張雄超,崔鋆昕,熊遲

1085

編輯:中冶有色技術(shù)網(wǎng)

來源:肖寒,周瑀杭,陳磊,張雄超,崔鋆昕,熊遲

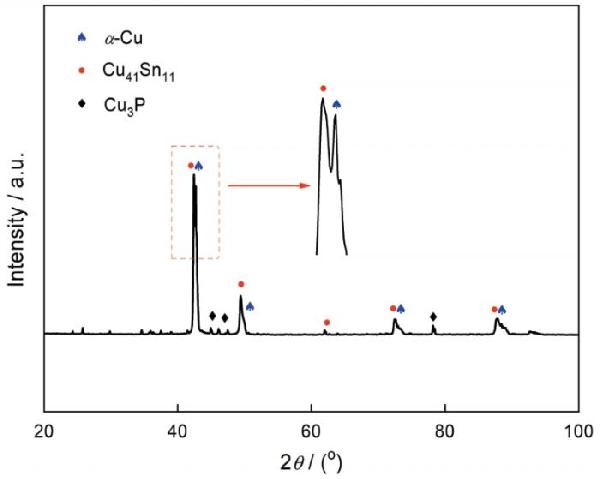

| Element | Cu | Sn | P |

|---|---|---|---|

| Point1 | 93.84 | 4.23 | 0.14 |

| Point2 | 70.90 | 25.45 | 0.20 |

分享 0

分享 0

舉報(bào) 0

舉報(bào) 0

收藏 0

收藏 0

反對(duì) 0

反對(duì) 0

點(diǎn)贊 0

點(diǎn)贊 0

中冶有色技術(shù)平臺(tái)

中冶有色技術(shù)平臺(tái) 2025年03月28日 ~ 30日

2025年03月28日 ~ 30日  2025年03月28日 ~ 30日

2025年03月28日 ~ 30日  2025年04月11日 ~ 13日

2025年04月11日 ~ 13日  2025年04月24日 ~ 27日

2025年04月24日 ~ 27日