全部

▼

搜索

熱搜:

位置:中冶有色 >

> 熱處理對Ti-6Mo-5V-3Al-2Fe-2Zr合金拉伸性能的影響

617

編輯:中冶有色技術(shù)網(wǎng)

來源:劉知多,張浩宇,程軍,周舸,張興君,陳立佳

617

編輯:中冶有色技術(shù)網(wǎng)

來源:劉知多,張浩宇,程軍,周舸,張興君,陳立佳

| Heat treatment | φ(αs)/% | λ/nm |

|---|---|---|

| HT1 | 34.8 | 88.75 |

| HT2 | 40.3 | 64.85 |

| HT3 | 37.5 | 47.15 |

| Heat treatment | Rp0.2/MPa | St.dev | Rm/MPa | St.dev | A/% | St.dev | Psp/GPa% |

|---|---|---|---|---|---|---|---|

| Before HT | 784 | 9 | 891 | 10 | 9.1 | 0.22 | 8.11 |

| HT1 | 1099 | 22 | 1196 | 26 | 5.1 | 0.17 | 6.10 |

| HT2 | 1256 | 19 | 1352 | 21 | 4.8 | 0.21 | 5.68 |

| HT3 | 1324 | 13 | 1421 | 11 | 7.7 | 0.13 | 10.94 |

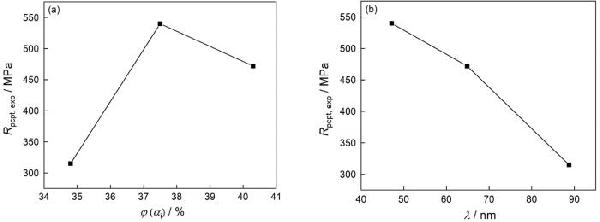

|

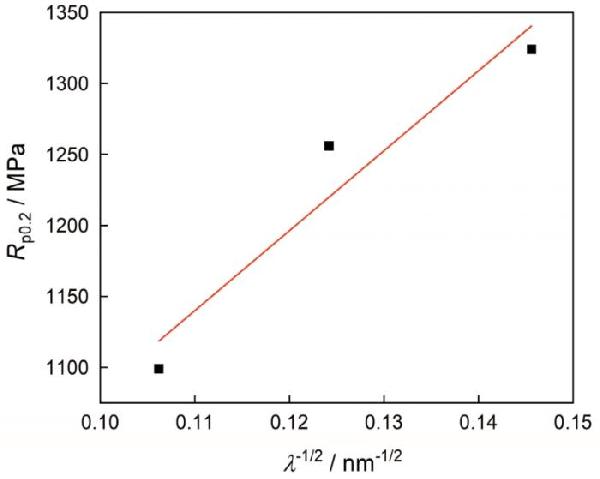

Heat treatment |

Rp0.2,exp /MPa |

Rν+Rss+Rgb /MPa |

Rpcpt,exp /MPa |

|---|---|---|---|

| HT1 | 1099 | 784 | 315 |

| HT2 | 1256 | 784 | 472 |

| HT3 | 1324 | 784 | 540 |

分享 0

分享 0

舉報 0

舉報 0

收藏 0

收藏 0

反對 0

反對 0

點贊 0

點贊 0

中冶有色技術(shù)平臺

中冶有色技術(shù)平臺 2025年03月25日 ~ 27日

2025年03月25日 ~ 27日  2025年03月28日 ~ 30日

2025年03月28日 ~ 30日  2025年03月28日 ~ 30日

2025年03月28日 ~ 30日  2025年03月28日 ~ 30日

2025年03月28日 ~ 30日  2025年04月24日 ~ 27日

2025年04月24日 ~ 27日